Custom apparel has become a key part of modern crafting and small-scale production. From personalized T-shirts to branded workwear, creators rely on methods that deliver clean results and long-term durability.

Two essentials play a central role in this process: a dependable Heat Press Machine and quality HTV Vinyl. When paired with thoughtfully designed equipment from HTVRONT, these tools help creators achieve consistent and professional outcomes.

Why HTV Vinyl Remains a Popular Choice

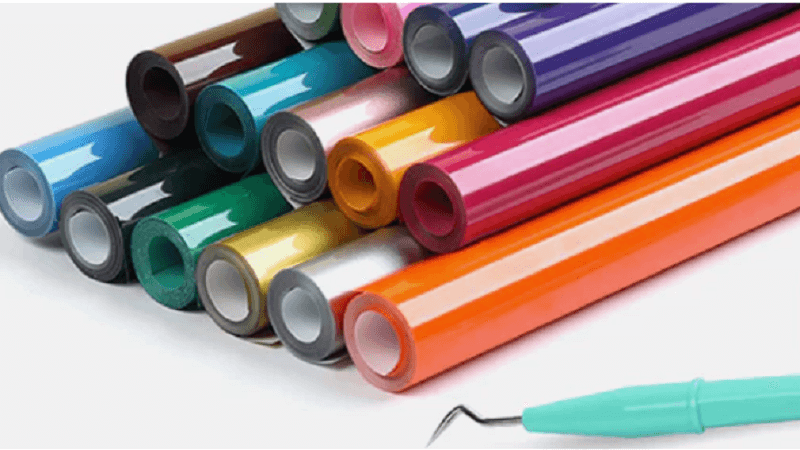

HTV Vinyl, or heat transfer vinyl, is widely used because it offers flexibility, durability, and creative freedom. It allows designs to be cut precisely and then bonded to fabric using heat and pressure. This makes it suitable for logos, text-based designs, layered graphics, and custom artwork.

One of the reasons HTV Vinyl continues to be widely used is its adaptability. It works across different fabric types and supports a variety of finishes, allowing creators to expand their product range without changing their core process.

The Role of a Heat Press Machine

Applying HTV Vinyl correctly depends heavily on controlled heat and pressure. A Heat Press Machine provides a stable environment where temperature, timing, and pressure remain consistent throughout the application process. This consistency helps ensure that vinyl adheres smoothly and stays intact over time.

Compared to alternative methods, a Heat Press Machine offers:

- Even heat distribution

- Predictable application results

- Improved wash durability

- Reduced material waste

For creators producing multiple items, this reliability becomes essential for maintaining quality across every piece.

How the Workflow Comes Together

A typical HTV project follows a structured process. The design is cut from HTV Vinyl, weeded carefully, positioned on the garment, and then pressed using a Heat Press Machine. Each step relies on precision, but the pressing stage is where everything comes together.

When the press delivers consistent heat and pressure, the vinyl bonds properly with the fabric. This creates a smooth finish that feels integrated rather than layered on top. Reliable equipment helps eliminate common issues such as lifting edges or uneven adhesion.

Why Many Creators Choose HTVRONT

In the crafting community, tool reliability directly affects productivity and confidence. HTVRONT has built a reputation for designing equipment that supports practical workflows without unnecessary complexity.

Their Heat Press Machines are known for stable temperature control and user-friendly operation.

HTVRONT tools are designed to support both beginners and experienced creators, making it easier to work consistently with HTV Vinyl. You can explore their full range of heat press and crafting equipment on the official HTVRONT website.

Consistency Supports Growth

For small businesses, consistency is more than a preference—it’s a requirement. Customers expect designs that look uniform, feel comfortable, and last through regular wear and washing. Using a dependable Heat Press Machine helps ensure that every application meets the same standard.

HTVRONT equipment supports this consistency by reducing the need for constant adjustments. When settings remain stable, creators can focus more on design and less on troubleshooting.

Creative Flexibility Without Added Stress

HTV Vinyl supports a wide range of creative ideas, from minimalist designs to layered graphics. With a reliable Heat Press Machine, creators feel more confident experimenting with new layouts and materials.

HTVRONT tools support this creative flexibility by offering predictable performance. As experience grows, creators can take on more complex projects without worrying about inconsistent results.

Long-Term Value of Reliable Equipment

Investing in dependable tools has long-term benefits. Fewer failed projects, less wasted material, and smoother workflows all contribute to better efficiency. Over time, this reliability saves both time and resources.

HTVRONT equipment is often chosen by creators who value tools that perform consistently over extended use. This dependability supports long-term creative and business goals alike.

Final Thoughts

Creating quality custom apparel requires a balance of technique and tools. A dependable Heat Press Machine ensures proper application, while HTV Vinyl provides flexibility and creative control.

Combined with reliable equipment from HTVRONT, these elements form a workflow that supports consistency, creativity, and professional results.

As demand for personalized apparel continues to grow, using trusted tools remains a practical foundation for long-term success.